ARTICLE

Ergonomic risk management

Don't be seduced by easy solutions: the importance of prioritizing the right ergonomic actions

Foreword

“If it seems too easy to set up… there’s a risk it won’t work.”

It’s a reality we often face in the field. As ergonomists, we see that too many company interventions are based on actions that appear simple, but have a limited impact on risk reduction.

When an OHS manager presents a series of recommendations to company management, it’s tempting to treat them all as equivalent. The result: the organization chooses the quickest and/or least costly to implement, believing it is making a good investment. But this can lead to a false sense of security and, above all, a waste of time and resources.

Beyond the potential ineffectiveness of the solutions chosen, this type of decision can lead to significant collateral damage. When the actions implemented do not have the desired effects, workers can quickly perceive a lack of seriousness or consistency in the prevention approach. This can lead to disengagement from health and safety initiatives, a loss of confidence in management and a feeling that their reality is not really being taken into account. Worse still, if an injury occurs despite the measures put in place, this can fuel a climate of cynicism or resignation. By repeating this cycle, the organization compromises its prevention culture and undermines employee buy-in to any future improvement initiatives.

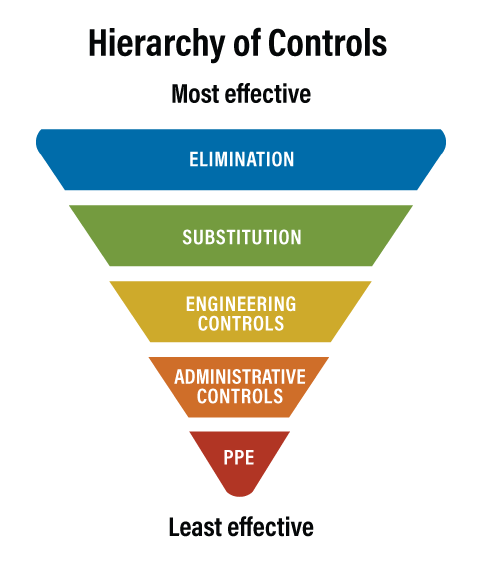

Hierarchy of risk control methods

The hierarchy of control measures is a fundamental principle in occupational health and safety (OHS), recognized by organizations such as NIOSH and INRS. It classifies different prevention strategies according to their effectiveness in reducing risks at source.

At the top of this hierarchy are the most effective measures, such as eliminating the hazard or substituting a safer process. Next come technical measures, administrative measures (procedures, schedules, training), and finally, at the bottom of the scale, personal protective equipment (PPE).

(Source : CCHST)

This principle is based on the idea that any preventive approach should begin by assessing the possibilities for action at the top of the hierarchy. In other words, before resorting to measures that are easier to implement, but less effective, we must systematically examine whether the risk can be eliminated, replaced or controlled at source.

All too often, organizations skip this step and opt straight away for administrative solutions or protective equipment, which merely mitigate the consequences without addressing the root cause of the problem.

By rigorously following this hierarchy, we can maximize the effectiveness of our interventions and build sustainable prevention.

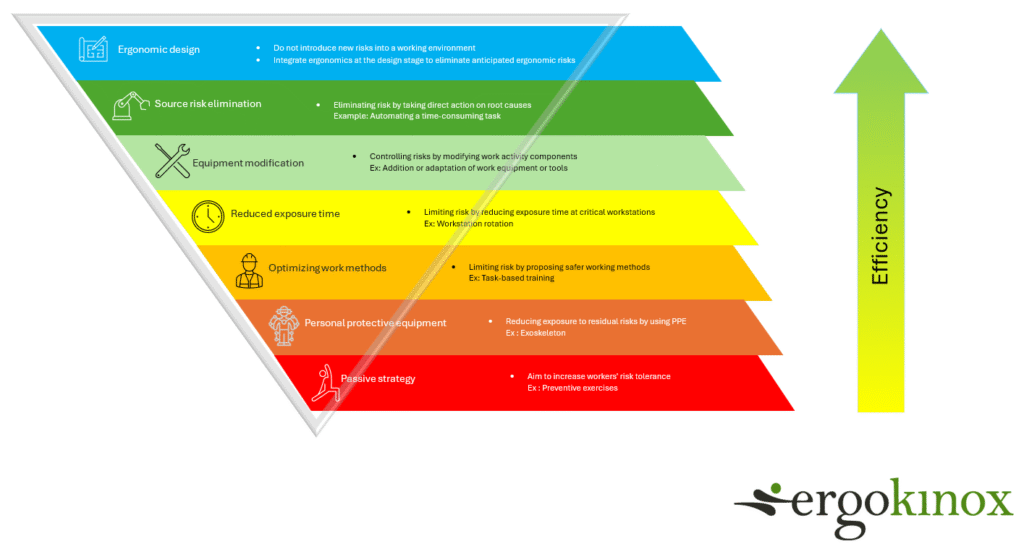

Hierarchy of prevention methods applied to ergonomic issues

At Ergokinox, we’ve found that the classic hierarchy of preventive measures, while effective, doesn’t always reflect the dynamics of ergonomics interventions. In this field, recommendations are often numerous, varied and sometimes perceived as equivalent, which can blur priorities. To better guide our customers, we have adapted this principle by developing an inverted pyramid of ergonomic measures.

Our approach aims to counter a phenomenon we frequently observe in the field: the easier a solution seems to be to implement (e.g. one-off awareness-raising, training, etc.), the more likely it is to be chosen, even if its real impact on risk reduction is limited.

Our pedagogical model enables decision-makers to better understand where to invest their efforts to achieve concrete, sustainable and measurable results.

7 levels: Where can you find the recommendations we offer?

Ergonomic design

LEVEL 1 – Integrating ergonomics from the design stage

This level aims to prevent risks right from the design phase of a work environment or workstation. The aim is to integrate ergonomic principles to avoid introducing unnecessary physical or cognitive constraints. This means designing healthy workplaces from the outset. This is the most effective and efficient strategy, but of course it’s not always available.

Ergonomic correction

LEVEL 2 – Eliminating risk at source

This is the most effective method of prevention: it involves completely eliminating the hazard by acting on its root cause.

For example, automating a repetitive or excessively demanding task can eliminate exposure to the risk.

LEVEL 2 – Equipment modification

When it is not possible to eliminate the risk, we can act on the equipment. Modifying tools, machines or workstations enables working conditions to be adapted to human capabilities, thus reducing excessive stress.

For example, integrating an adjustable table into a palletizing task reduces the amplitude of certain constraining trunk movements by limiting the vertical displacement of the load.

LEVEL 4 – Reducing exposure time

Limiting the time spent on high-risk tasks or workstations can reduce the impact on health. Job rotation and scheduled breaks are effective ways of controlling exposure to physical or mental stress.

For example, job rotation can help reduce the risk of cumulative strain by limiting the number of hours a worker is exposed to repetitive handling of loads.

LEVEL 5 – Optimizing work methods

Adopting safer ways of working can reduce the occurrence of activity-related disorders. Training workers in safer principles and techniques helps prevent injuries.

For example, training in the principles of safe handling makes workers aware of the hazards associated with their task, and teaches them safer methods for reducing the risk of injury.

LEVEL 6 – Personal protective equipment (PPE)

PPE is designed to protect workers from residual risks when they cannot be eliminated or reduced by other means. Although useful, they are less effective than upstream measures, as they do not eliminate the hazard.

For example, exoskeletons can reduce fatigue in certain joints during physically demanding tasks.

LEVEL 7 – Passive strategy

These are measures that rely on the worker’s tolerance or adaptation, rather than on risk reduction.

For example, warm-up exercises or active breaks are designed to strengthen the individual’s ability to withstand stress.

Conclusion: Prioritize with discernment

In short, every preventive measure has its place, but not all are equal.

In ergonomics, it’s essential to resist the temptation of easy solutions and to structure actions with an eye to their anticipated effectiveness.

For example, if workers have to manually lift 25 kg loads repeatedly, putting up a “Remember to bend your knees!” sign next to the workstation is not an effective solution.

At Ergokinox, we believe that a better understanding of the hierarchy of interventions allows us to act more effectively. Even if one solution seems more economical in the short term, it may turn out to be the most costly once an injury occurs and the organization has to deal with the human, financial and operational impacts.

– Nicolas Paradis, CCPE-certified ergonomist