ARTICLE

Why are exoskeletons so popular?

Foreword

Why are exoskeletons proliferating in Quebec and Canadian workplaces?

This very real phenomenon is neither a fad nor a mere technological fascination.

In a context where robots are still not widely used and musculoskeletal disorders are still common, these devices offer support that may prove relevant. In this article, I propose to investigate on the growing interest in exoskeletons, and offer some insights on how to evaluate them wisely.

“Would you have an exoskeleton to suggest for our workers […]?”

It’s a message I first received in 2022 and have continued to receive ever since…

Transported now to 2025, Ergokinox and I are in several companies, exoskeletons in hand, for comparative trials.

Why are industrial exoskeletons so popular with Quebec and Canadian companies?

It’s a big question, but I’ll try to answer it in a few points, but first let’s lay down some common ground about the Canadian economic context:

Canada’s automation and robotization deficit

Historically, the Canadian economy has developed around the exploitation and export of natural resources such as timber, minerals, oil and agricultural products. This orientation has shaped an industrial fabric more focused on primary processing than on high value-added production requiring advanced technologies. Unlike countries such as Germany, Japan or even South Korea, which were early adopters of industrial modernization, robotization and high precision, Canada has never adopted a strong national industrial strategy along these lines.

Structurally, Canada’s manufacturing sector is largely made up of small and medium-sized enterprises (SMEs), which account for over 90% of the establishments that drive the economy and contribute almost 50% of GDP. These companies, often family-owned or local, have limited investment capacity. The purchase of industrial robots or automated systems requires substantial capital, a change in production methods and advanced technical skills – all barriers that many SMEs are reluctant to overcome. What’s more, the return on investment may seem uncertain in the short term, especially in a fluctuating economic environment. This can fuel a culture of technological risk aversion.

Added to this is difficult access to suitable sources of financing. Although governments offer innovation assistance programs (tax credits, subsidies, etc.), these mechanisms are sometimes complex, inflexible, or poorly adapted to the reality of small businesses. Many simply don’t have the resources to navigate the bureaucracy required to take full advantage of them.

At the same time, the culture of technological innovation remains unevenly spread across Canada. Although the country boasts internationally renowned research centers, collaboration between these centers, universities and manufacturing companies remains weak. Technological innovations are often confined to academic circles or start-ups in the digital sector, with no real transfer to traditional manufacturing industries.

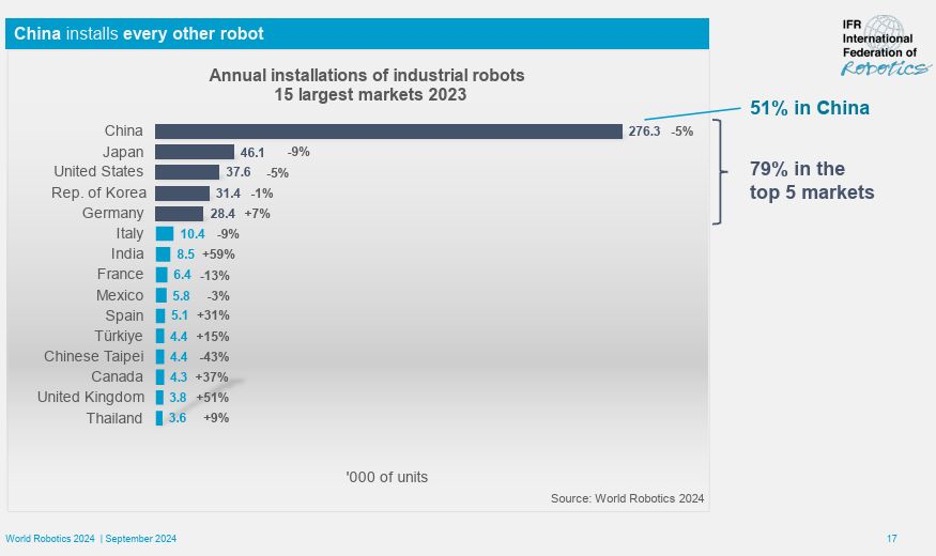

In terms of industrial robotics installations, China dominates (51% of global installations), while the top 5 markets account for 79% of all industrial robots deployed worldwide.

(Source : World Robotics Press Conference 2024)

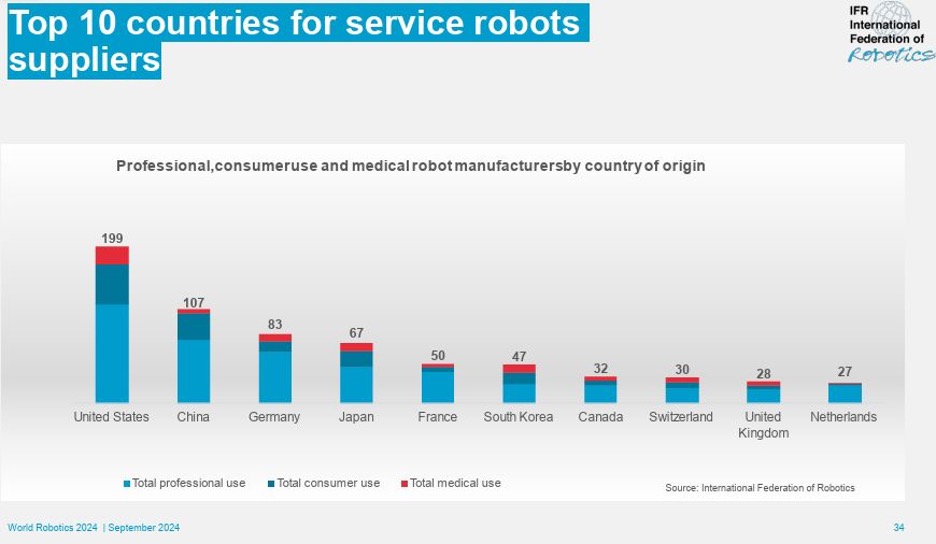

Meanwhile, as a Canadian, we are the world’s 7th largest supplier of robots, showing that we have the capacity for innovation, but our domestic industrial implementation is clearly deficient.

(Source : World Robotics Press Conference 2024)

For a long time, this robotization deficit was maintained with little apparent impact. But since the turn of the 2000s, globalization, the rise of China, massive offshoring and, more recently, the disruption caused by the pandemic and labor shortages have highlighted the limits of the Canadian model. Companies are now faced with a double pressure: to remain competitive on the world stage, while maintaining production despite an increasingly scarce workforce.

So, although we are seeing a growing awareness and efforts to modernize the means of production, catching up is a long and costly process. The gap accumulated over the decades cannot be closed without a structural transformation, supported by clear policies, improved access to financing for production technologies, and greater synergy between the worlds of research, innovation and manufacturing.

Background to the demographic crisis in Canada and Quebec

Another factor often overlooked is the historically affordable cost of labor in certain regions of Canada. This reality has long reduced the incentive to automate. As long as companies could hire easily at low cost, automation did not appear to be a priority. However, this model is becoming less and less viable, not least because of the rapidly aging workforce and the growing shortage of skilled labor.

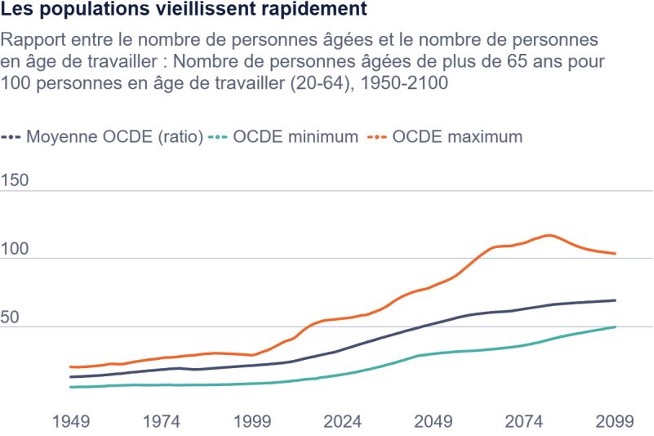

In Canada, the number of people over the age of 65 as a proportion of the workforce continues to rise. This demographic reality is putting increasing pressure on the Canadian government to extend the retirement age to 67 (C.D. Howe Institute, 2025). The reality of demographic aging is not unique to Canada; this tangent is common to OECD and industrialized countries.

(Source : OCDE)

The accelerating shortage of skilled labor, exacerbated by an aging demographic and the retirement of baby-boomers, is forcing companies to look for alternative solutions to maintain their production capacity. The pool of young, physically fit workers is shrinking, while heavy manual tasks remain in many sectors such as construction, agri-food, logistics and industrial assembly.

Now, why are exoskeletons so popular?

In this context, exoskeletons appear to be a technological solution for job retention for several players, enabling experienced workers to extend their careers by reducing musculoskeletal risks.

In Quebec, we are witnessing a rise in social and legal expectations in terms of occupational health and safety (through the Act to modernize the occupational health and safety system, for example).

Musculoskeletal disorders (MSDs) are still one of the main causes of absenteeism, early retirement and costs for compensation systems. Yet, in an environment where MSD prevention is becoming a priority, exoskeletons potentially become a complementary tool to ergonomic intervention, offering direct physical support to workers.

In terms of technology, the last few years have seen a rapid maturation of physical assistance technologies.

Their large-scale implementation is now possible thanks to the rise in technological maturity, better known as TRL (Technology Readiness Level).

TRL is an indicator that measures the degree of development and reliability of a technology, from conceptual idea (level 1) to a fully deployed product in a real operational environment (level 9). However, in recent years, a large proportion of the exoskeletons available on the market have gone from the experimental stage to high TRL levels (levels approaching 7).

This means that exoskeletons are no longer prototypes or tools to be validated in the laboratory: they are tested, proven and adapted to real industrial environments, including handling, assembly, logistics or construction.

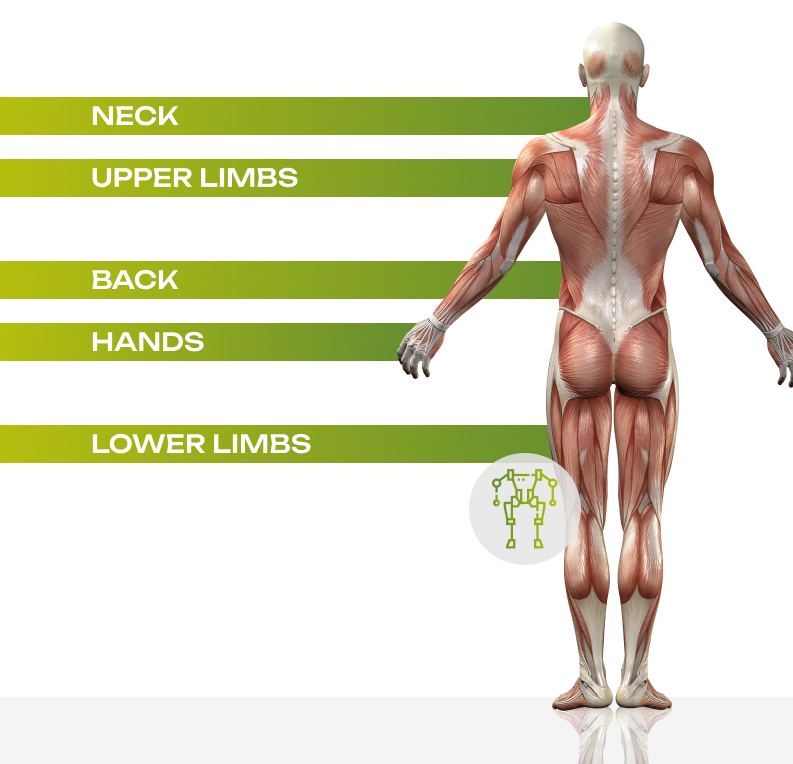

Exoskeletons are no longer just prototypes or heavy devices from the military or medical fields: they are becoming lighter, more affordable, adaptable and targeted to various industries. Some support the shoulders for work at height, others the lumbar region for materials handling, or the lower limbs for prolonged static positions. Over the past few years, we’ve seen a race towards greater specialization as manufacturers seek to prove that their products integrate better than the competition in real-world environments, without compromising workers’ mobility or autonomy.

Although promising, the use of exoskeletons in the workplace naturally raises a number of questions:

Is it profitable?

Is it accepted by workers?

Does it really work?

One of the major obstacles to the adoption of emerging health and safety technologies is the perceived financial risk. Acquiring exoskeletons, testing them in the field, training staff and adapting workstations represents a significant initial investment – especially for SMEs.

This is where government assistance programs, subsidies and pilot projects run by institutional partners (such as IRSST or CNESST) play a key role. By reducing the company’s share of the risk, these measures make it possible to test concrete solutions without incurring all the costs, while gathering valuable data on their effectiveness. In this sense, these programs act as catalysts for innovation in OHS, lowering the barrier to entry for physical assistance technologies.

At the same time, there is a growing number of case studies being disseminated throughout the Quebec network. Institutions such as the IRSST, sectoral committees and OHS groups are publishing more studies on the subject and concrete testimonials from companies as well.

This sharing creates a powerful emulation effect. When a company in the same sector or region sees that a peer has integrated an exoskeleton with positive results (reduced RSI, improved comfort, increased productivity), it is naturally more inclined to consider a similar approach. Professional word-of-mouth, backed up by field data, reinforces the credibility of the technology and reduces fear of the unknown.

These case studies also play an important educational role: they show how exoskeletons can be integrated into an overall ergonomic approach, by explaining the key stages (work analysis, choice of model, support for workers, effects monitoring).

The elephant in the room

While exoskeleton manufacturers are increasingly touting the benefits in terms of productivity, prolonged endurance and performance, it’s imperative to remember the primary purpose of these devices: to reduce physical constraints on the human body.

Preventing musculoskeletal disorders (MSDs), prolonging working capacity, and promoting job retention.

When the exoskeleton is perceived and used as a tool for increasing workload, its essence is distorted. It ceases to be a supportive device and becomes a vector for overstraining and even new pathologies.

Marketing speeches about “increased efficiency”, “faster production cycles” or the possibility of “lifting more, for longer” are seductive for some companies, but can create implicit or explicit pressure on workers. This pressure, even if unintentional, can take the form of :

- Increased production rates.

- Reduced rest periods.

- An increase in the number of tasks assigned to a position.

In other words, the exoskeleton, which is supposed to provide relief, becomes a compensated overload factor, masking rather than correcting discomfort. Not only does this compromise the long-term effectiveness of the device, but it can also lead to new physical risks, notably through load transfers onto the body and/or compensatory postures that distress the worker.

A change that requires support

To avoid this drift, it’s crucial that the integration of exoskeletons is framed by a rigorous ergonomic approach, where the aim is never to do “more”, but to do things better and healthier.

This involves :

- An assessment of actual job requirements.

- Support for change, including workers.

- Training in the responsible use of the device.

- Post-implantation monitoring of effects on health and physical load.

The exoskeleton does not replace primary prevention (layout, work organization, adapted tools), but is a potential complement in situations where reduction at source is not possible.

Now,

Each industry has its own unique constraints:

– Varied work environments (dust, splashes, driving vehicles, etc.)

– Task-specific movements and rhythms

– Special needs

– Different corporate cultures and demographics

Why risk choosing unsuitable equipment when you can validate your decision with concrete data?

Visit our dedicated page to find out more about our comparative testing process, and let’s discuss your needs.

– Hamza Azzouzi, ergonomist EA